Pfening's conditioning systems are custom-engineered to create the perfect environment to proof and ferment yeast-based products or cool finished goods after baking.

Pfening’s excellence in temperature and humidity control is recognized throughout the industry. For over fifty years, we have partnered with manufacturers of automatic proofers to provide customized HVAC systems for their equipment.

Proofing systems with precise temperature and humidity control ensure consistent size, texture, and appearance of your raised dough product.

Since 1940, Pfening Proof Boxes have set the industry standard for reliable, consistent proofing. Pfening Fermentation Rooms and Dough Retard Rooms have also set high standards for equipment quality and performance.

Pfening can provide the entire insulated enclosure, conditioning system, controls, or any portion of the system to fit your bakery’s needs. We can also design a custom solution to retrofit your existing equipment or room. Select the system you need in the navigation window for more information about each.

Rack Proofers

Pfening proofing systems are specifically engineered for our customers’ applications. Proven designs ensure sufficient heat and humidity are delivered to the proofer enclosure to properly raise yeast-based dough products. Airflow is key to creating consistent temperature and humidity throughout the proofer. Pfening proofers are designed to achieve in excess of 100 air changes per hour.

Rack Proofers have a rigid, durable design to withstand the rigors of an industrial bakery. The systems feature Pfening’s air delivery and circulation system to ensure homogenous temperature and humidity throughout the enclosure.

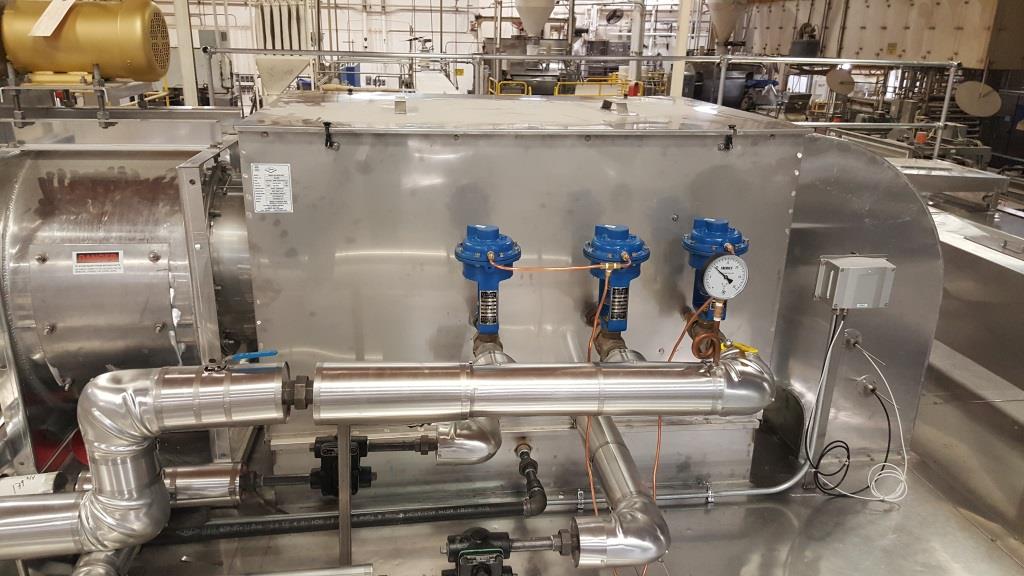

Humidity can be added via live steam injection or atomizing spray nozzles with water filtration and UV sterilization. Proofer Conditioning Systems are designed for use with customers’ existing enclosures or automatic (spiral or step) proofing systems.

This animation depicts air flow through a supply duct downspout. These downspouts extend low into the enclosure. This drives heat down to heat the floor, eliminating cooler areas that impede proofing. Additionally, the downspouts are equipped with Venturinozzles, which draw air in from the enclosure into the downspout. This highly efficient airmixing action helps to balance heat and humidity levels throughout the proofer enclosure. The result is a consistent size, texture, and appearance of your raised dough product.

Fermentation Rooms

A fermentation room is an insulated enclosure that will help maintain consistenttemperature and humidity allowing repeatable fermentation regardless of ambientconditions

Pfening designs and builds air handling units constructed of stainless steel with a heavy-gauge, all-welded sump pan with a completely removable top to allow for cleaning/maintenance access and long-lasting aluminum air filters.

The evaporator/condenser coil is designed with a low number of spaced fins to keep the coil from clogging with dust and allow for easier cleaning. The Heat Pump Compressor/Condenser/Evaporator Unit allows the Pfening air handling unit to provide either heating or cooling as required. The support frame for the air handling unit and fan is constructed of non-corrosive aluminum, allowing the air handling unit to be supported independently of the insulated enclosure.